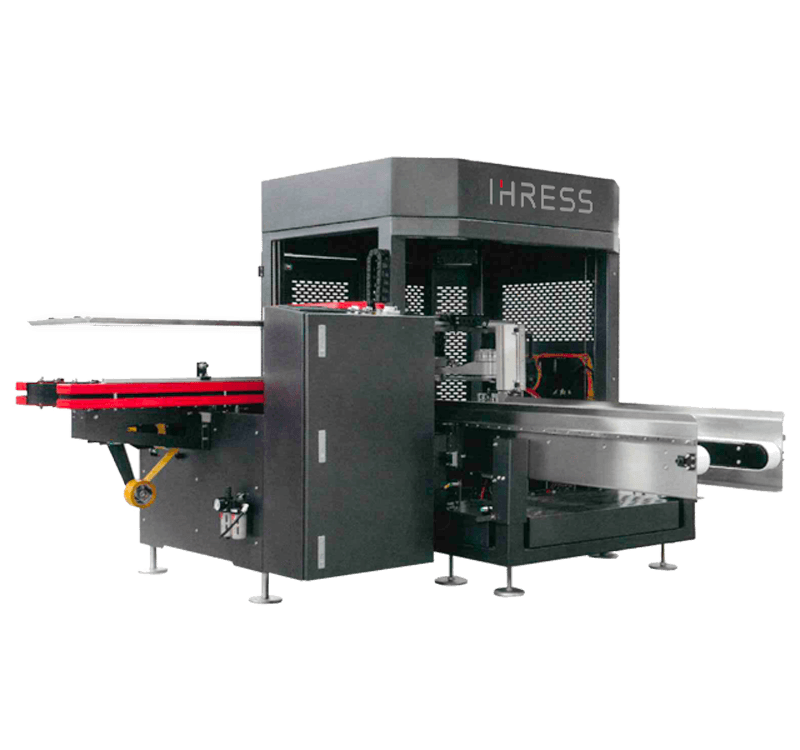

Automatic case erector with robotic arm - iBEM200 RB

The Automatic case erector with robotic arm iBEM200 RB is the most advanced solution for companies that need automate case erecting at high speedswithout sacrificing precision and flexibility. With state-of-the-art robotic technology, it is perfect for production lines that are looking for optimize the end of lineto improve productivity and reduce operating costs.

What is the iBEM200 RB Robotic Arm Automatic Case erector?

The iBEM200 RB combines robotics and industrial technology to offer a box forming machine single-formatcapable of working up to 30 cases per minutedepending on the size and material of the packaging. Your integrated robotic arm enables high-speed operations with total reliability, reducing errors and unplanned downtime.

This forming machine is ideal for companies with large order volumessuch as logistics centers, automated warehouses or manufacturing plants that need a robust and scalable solution.

Technical features of the automatic case erector with robotic arm

Below, we present the main features of the automatic case erector with robotic arm iBEM200 RBa solution designed to offer performance, precision and reliability in demanding production environments.

TECHNICAL DATA SHEET

| Specification | Detail |

|---|---|

| Production | Up to 30 cases per minute |

| Flap closure | 48 to 72 mm seal |

| Max. coil diameter | 220 mm |

| Dimensional adjustment | Automatic |

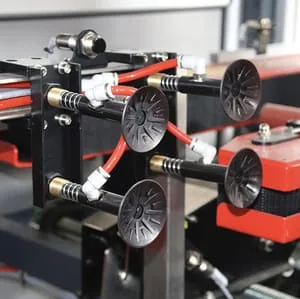

| Pneumatic components | AIRTAC |

| Electrical voltage | 220 V / 50 Hz |

| Installed power | 4.6 kW |

| Compressed air consumption | 6 bar |

| Total weight | 1,140 kg |

| Control panel | Intuitive production configuration |

| Robotic arm | High speed case erecting |

Competitive advantages of the automatic case erector with robot arm

Why choose this automatic case erector with robotic arm versus other options?

Up to 30 cartons/minute to meet high demands.

Quick format change without stopping the line.

Reduction of errors and material waste.

Quality components such as AIRTAC guarantee a long service life.

Intuitive control panel for real-time adjustments.

Compatible with other automated packaging solutions.

WE ADAPT THE MACHINERY TO THE PACKAGING PROCESS

Automatic case erector with robotic arm applications

Examples of use: In fulfillment warehouses where thousands of daily shipments are handled, in factories with assembly lines that require continuous packaging or in dropshipping platforms that must optimize time per order.

The iBEM200 RB is perfect for companies that need high packing rates in sectors such as:

Food industry

Boxes for bottles, cans or packaged products.

Multinational logistics centers

Preparation of boxes for automated picking.

Pharmaceutical distribution

Safe and stable format of small boxes.

Automotive and spare parts

Online sales companies with high order volume

Frequently Asked Questions (FAQs)

What is the price of the iBEM200 RB Robotic Arm Automatic Case erector?

The price depends on the configuration, volume and accessories required. Request your personalized quote and receive free advice.

How does the iBEM200 RB work?

The robotic arm automatically picks, forms and closes single-format boxes, adjusting dimensions in real time. Everything is managed from an intuitive control panel.

What maintenance is required?

Thanks to its robust design and quality components, maintenance is minimal. Pneumatic and robotic arm overhaul is recommended according to working hours.

What are the alternatives?

We have automatic case erectors without robotic arm for medium productions and multiformat equipment. We help you choose the solution that best suits your business.

What do other customers think?

Customers highlight its reliability, speed and ease of useThe system can be integrated into existing lines.

Who is this automatic case erector with robotic arm for?

If you have a high volume production lineIf you are a logistics warehouse or ecommerce business with large order peaks, this machine is for you. It is ideal for businesses looking for advanced automationcost control and high operational efficiency.

OPERATION

How does the iBEM200 HS case erector work?

The iBEM200 RB is a automatic case erector with robotic arm designed for companies that need a training system reliable, continuous and ultra-precise even in high volume productions. Thanks to its integrated robotic armThe picking, forming and closing of boxes is done at high speed and with total consistency.

Its robotic technology allows adjust dimensions automaticallyThe inner mechanism folds and closes the bottom flaps with maximum uniformity. In addition, its design modular and robust facilitates integration into existing packaging lines, optimizing the workflow without major construction work or downtime.

It is the ideal solution to make the leap to a advanced end-of-line automation, maintaining operating costs under control and reducing the need for constant maintenance.

Request your demonstration with no obligation!

Take your production to the next level with the Automatic case erector with robotic arm iBEM200 RB.

Contact our team for more information, pricing and customization options.

+34 936 555 600

Monday to Friday from 7:00 a.m. to 3:00 p.m.

P. I. La Serra

Camí de la caseta 3 A 08185 Lliçà de Vall (Barcelona) Spain

Email: info@ihress.com

More models of case erectors

At Ihress we offer you a complete range of automatic and semi-automatic case erectorsdesigned to suit the specific needs of each customer. Like manufacturers and experts in packaging machineryWe have a team of specialized engineers that allows us to customize each equipment according to the type of cashbox, production rate and sector of activity of your company.

iBEM100

iBEM200-HS

iBEM300

iBEM300

Automatic up to 6 cartons per minute. Specially designed for large format boxes.

More details