Complete lines of packaging machinery

Intelligent and efficient automation for the end of the line

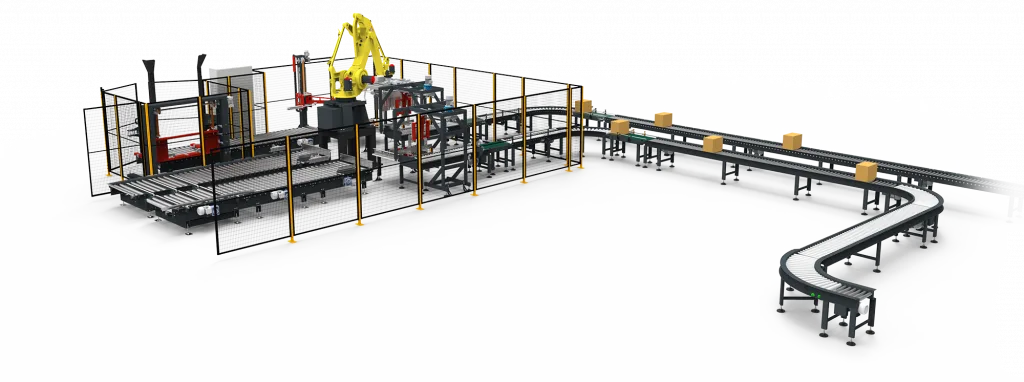

The complete lines of packaging machinery are integrated solutions designed to optimize the end-of-line production process in high-demand industries. These automated lines include stretch wrapping, forming, case packing and pick & place systems that enable fast, accurate packaging without human intervention.

Tailor-made according to each customer's requirements, these solutions are ideal for sectors that require speed, efficiency and safety in product packaging. Our more than 30 years of design and manufacturing experience ensures superior performance in every installation.

Packaging systems

Competitive advantages of our packaging solutions

| Systems and applications | Specifications |

|---|---|

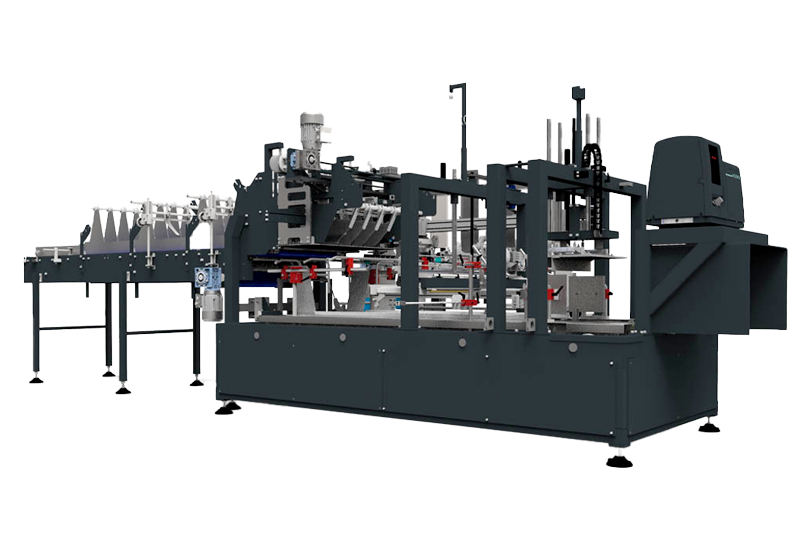

| Wrap Around System | High-speed case erecting and case packing with automatic adjustment |

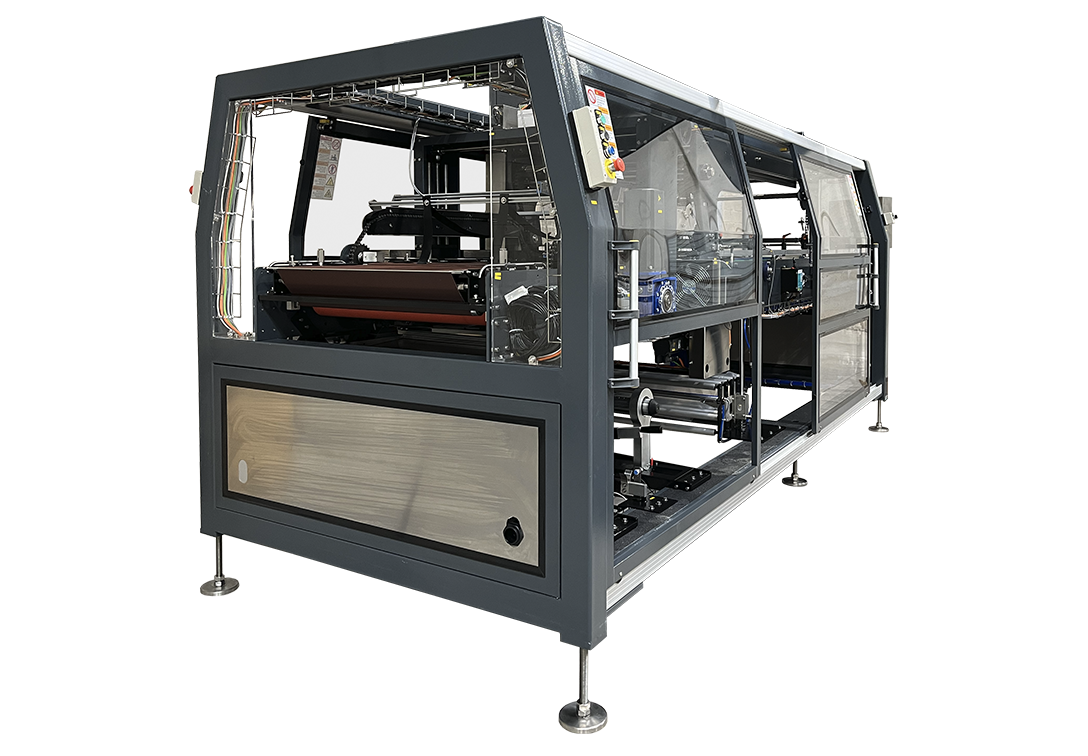

| Shrink Wrap System | Shrink-wrapping with shrink film; full process automation |

| Pick & Place | Robotic product handling, adaptable to multiple formats and weights |

| Process speed | Up to 120 units per minute, depending on configuration |

| Compatibility | Integration with ERP, SCADA, and industrial automation lines |

| Supported materials | Plastic film, corrugated cardboard, trays, cartons, boxes, pallets |

| Energy consumption | Energy optimization with intelligent standby systems |

| Security | CE certification, presence sensors, perimeter fencing, emergency shutdown, etc. |

Competitive advantages of our packaging solutions

In contrast to traditional or semi-automated systems, our systems are complete lines of packaging machinery are highlighted by:

- Full end-of-line automationwithout direct human intervention.

- Significant reduction of errors and increased accuracy.

- Operating cost savings and efficient consumption of materials.

- Modular and scalable designadaptable to productive growth.

- Increased safety for operatorsminimizing occupational hazards.

- Optimized maintenance with remote diagnostics and accessible components.

Applications and industries using complete packaging lines

These solutions are especially recommended for sectors with high product turnover and the need for continuous efficiency:

- Food industrypackaging of boxes, bottles or snack packs.

- BeveragesPack formation and palletizing of bottles or cans.

- Logistics and distributionPackaging and palletizing of mixed loads.

- Constructiongrouping of materials such as tiles, tools or metal parts.

- PharmaceuticalsPackaging of sensitive products, complying with traceability regulations.

Concrete example: a beverage company bottling 10,000 units per hour can reduce its operating staff by 70% and increase the consistency of its packaging by more than 90%.

WIDE RANGE OF SOLUTIONS

Get to know our complete catalog of customized solutions for any packaging need your company or business may have.

Frequently Asked Questions (FAQs)

What is the price of a complete line of packaging machinery?

Pricing varies depending on design, production volume and components required. Contact our team for a quote. customized quote.

How does an automatic packaging line work?

From case erecting to palletizing, everything is done by automated modules that synchronize with each other, without the need for direct human intervention.

What maintenance do these systems require?

We recommend a preventive maintenance every 6 months. Our systems include diagnostic sensors and remote assistance to reduce downtime.

What are the alternatives to these systems?

Semi-automatic systems are available, but require more personnel and are less efficient than full lines. Complete lines offer a faster return on investment.

What do customers think?

Leading companies in sectors such as food and logistics have emphasized the reliability, ease of use and technical support as major differentials.