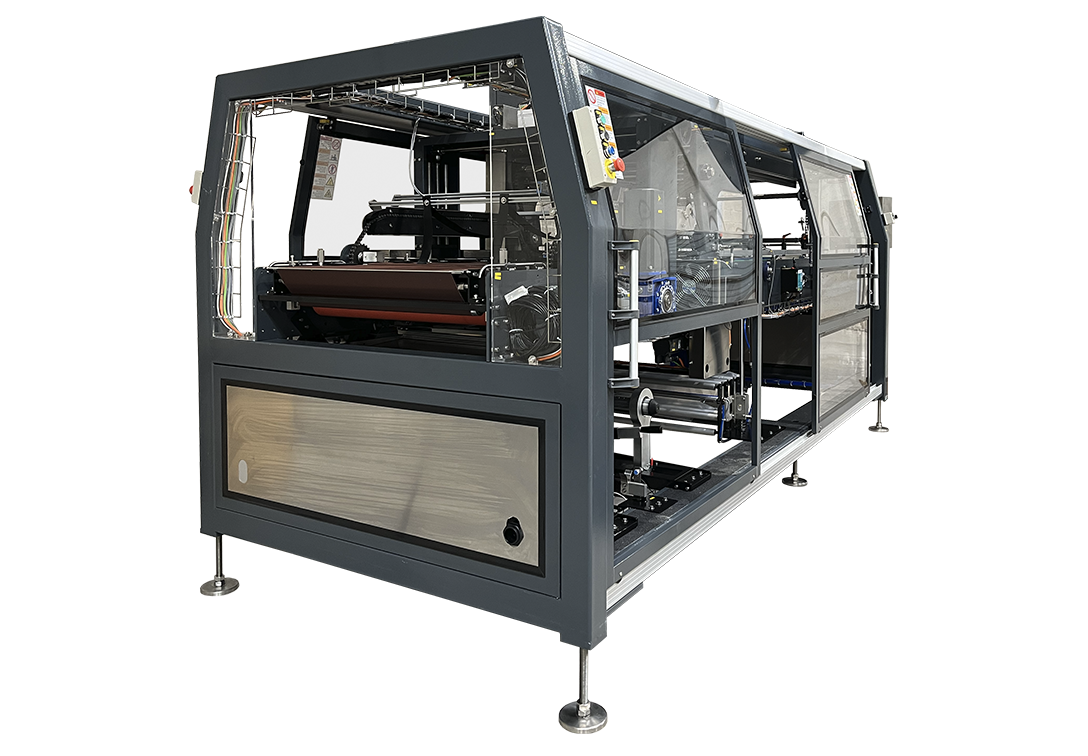

Shrink Wrap Wrap Wrapping Machines : SWM System for industrial packaging

What are Shrink Wrap banding machines?

The Shrink Wrap Wrap Wrapping machines are machines designed to package grouped products by means of a shrink film. In the case of the continuous banding machines SWMis used, a welding rod and a hot chamber to wrap the package safely, quickly and homogeneously. This type of machinery is essential in production lines where speed, product presentation and protection during transport are critical.

Capable of achieving up to 35 packages per minuteSWM banding machines from IHRESS are designed for industrial companies looking for efficiency, format versatility and operational reliability.

Technical characteristics of the SWM system

The SWM wraparound banding machines stand out for their consistent performance and their ability to adapt to multiple formats and line configurations. Below are their key technical specifications:

TECHNICAL DATA SHEET

| Specification | Detail |

|---|---|

| Production | Up to 35 packages per minute (depending on model and product) |

| Types of configuration | 2×2, 3×2, 4×3, 6×4 |

| Product grouping | Integrated mechanical system |

| Format change | Manual |

| Inlet conveyor | In line or at 90°, as required |

| Carton warehouse | Automated |

| Shrink chamber | With pneumatic seal and digital temperature control |

| Inbound and outbound transportation | Motorized belts |

100% AUTOMATED PACKAGING SYSTEMS

Competitive advantages of Shrink Wrap SWM banding machines

These banding machines are designed to offer high performance with flexibility of useThe system can be adapted to different types of packaging and production environments.

Up to 35 packages/minute without sacrificing quality.

Adapt the grouping to commercial needs.

Manual system optimized for speed.

Ideal to be integrated into new or existing lines.

Hot chamber with digital control.

Reduce errors and improve consistency.

Food, cosmetics, beverages, cleaning...

WE ADAPT COMPLETE LINES TO EACH SECTOR

Recommended applications and sectors

The Shrink Wrap Wrap Wrapping Machines SWM are used in numerous industries that require bundled or shrink-wrapped packaging for transportation and distribution. Some examples:

Food and canned food

Grouping of cans, jars, bottles, packages...

Cosmetics and personal care

Promotional product packs.

Chemical sector

Grouping of detergents or aerosols.

Pharmaceuticals

Secondary packaging for logistics and warehousing.

Frequently Asked Questions (FAQs)

What is a Shrink Wrap banding machine?

It is a machine that bundles products using shrink film that adheres to the package as it passes through a lime chamber.

How does the format changeover work?

It is a system manual but agiledesigned for operators who must quickly switch from one type of configuration to another.

What are the advantages over a traditional baler?

The banding machine allows group products with direct commercial finish, ideal for promotional packs or direct distribution to the point of sale.

What kind of products can I wrap with a SWM?

From bottles and cans to small crates. The system can be adapted by means of configurable 2×2, 3×2, 4×3 or 6×4 formats.

What is the price of a SWM wrap-around banding machine?

The price depends on the model, desired production and input/output configuration. Request a customized proposal according to your needs.

Who are these banding machines for?

SWM banding machines are designed for:

- Industrial companies in need of shrink-wrapped packaging.

- Factories handling medium and high production volumes.

- Businesses that need a system that combines flexibility + speed.

- Installations with space for modular or in-line integration.

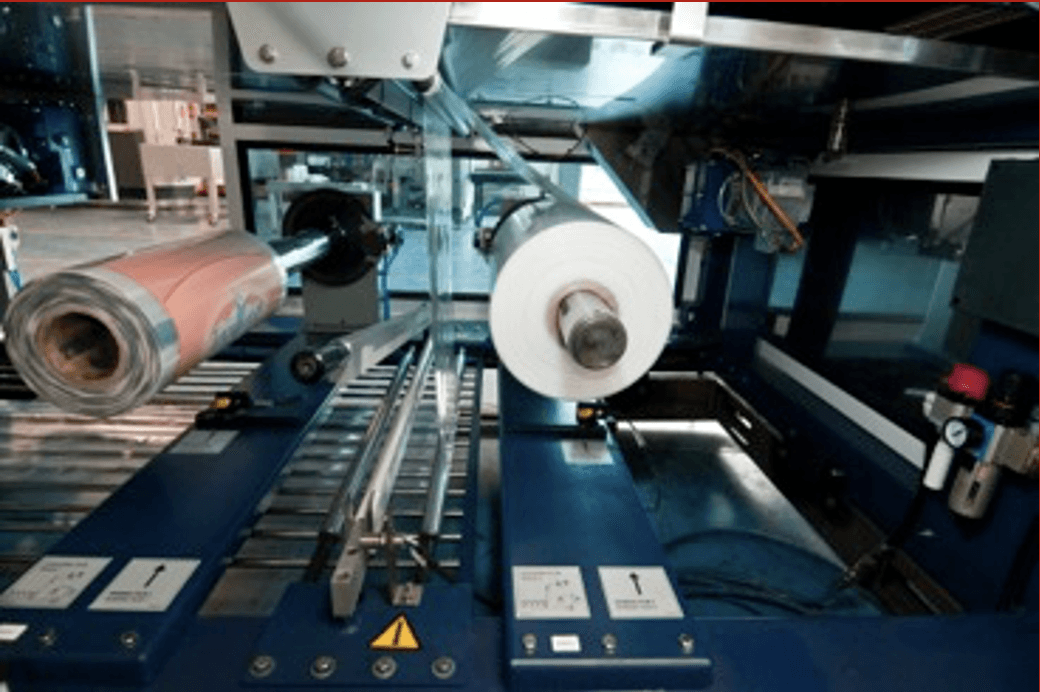

OPERATION OF A WRAP-AROUND BANDING LINE

How does the Shrink Wrap banding machine work?

Optimize your packaging line with SWM technology

If you are looking for a automatic shrink film packagingIHRESS SWM wrap-around banders are the perfect alternative to take your production to the next level.

+34 936 555 600

Monday to Friday from 7:00 a.m. to 3:00 p.m.

P. I. La Serra

Camí de la caseta 3 A 08185 Lliçà de Vall (Barcelona) Spain

Email: info@ihress.com