Case sealers

Pre-sealers Semi-automatic crate handling

The semi-automatic sealing machines are versatile tools designed for case sealing, and are available in different shapes and sizes to suit various logistic needs. These machines are especially useful in environments where a series of boxes of the same size need to be sealed, offering an efficient and convenient solution for the packaging process.

Lateral drag belts

Seal tension adjustment

Manual dimensional adjustment

Sealed double head

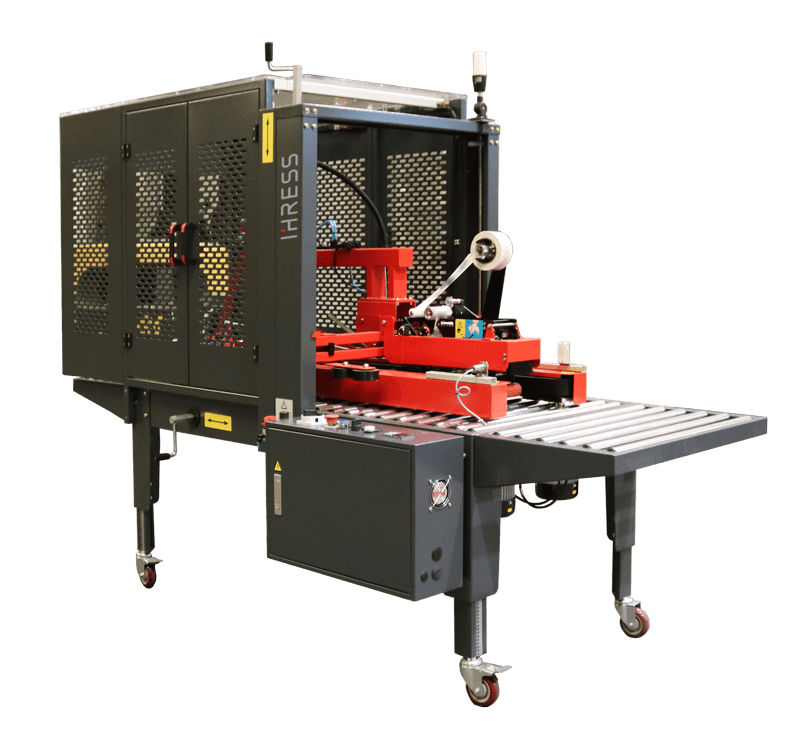

Case sealer models semi-automatic

WIDE RANGE OF SOLUTIONS

Get to know our complete catalog of customized solutions for any packaging need your company or business may have.

Case sealer models automatic

Model iP35

Automatic case sealer for single-format cartons

The automatic case sealers are machines designed to close and seal boxes efficiently and without the need for manual intervention, making them a vital tool for companies with high production volumes. These machines automate the sealing process, using adhesive tape or seals, and are especially useful in large industries where the volume of packaging is considerable.

Model iP35-AT

Automatic single-format sealing system

The iP35-AT system allows the addition of a case sealer to an automated packaging line. This case sealer can be fully automated.

Model iP45

Multi-format automatic case sealer

The iP45 system allows the addition of a case sealer to an automated packaging line. This case sealer can be fully automated. Up to 14 cartons / minute

Frequently Asked Questions about case sealers

Why buy a semi-automatic case sealer?

Semi-automatic sealing machines are an excellent choice for production lines that work with lots of boxes of the same size. Their simple manual programming allows the desired format to be set without complications, which makes them an ideal solution for fast, practical and cost-effective.

In addition, they offer a versatile useAlthough they are optimized for homogeneous boxes, they can be adapted to different needs depending on the user's operation.

What are the benefits of a semi-automatic sealer?

Operational efficiencyThey increase sealing speed and reduce downtime.

Cost reductionThey reduce the need for skilled labor and reduce the time spent per operator.

Easy handlingIntuitive design and manual programming make it easy to use without advanced technical training.

What are the advantages of an automatic case sealer?

Automatic sealing machines are ideal for companies that handle high packaging volumes and need to optimize their resources to the maximum:

Increased efficiencyFully automate the sealing of boxes, speeding up the process.

Reduction of workloadThey reduce the manual intervention, relieving the physical effort of the operators.

Consistent qualityThey guarantee a uniform sealing, better protecting the products and maintaining quality standards.

What features should I consider when choosing an automatic sealing machine?

When selecting an automatic sealer, it is important to consider:

Tape typeSome models use polypropylene (PP) tape, PVC or gummed paper, depending on the type of packaging required.

Size of boxesThere are models designed for specific sizes and others that are more flexible to handle different dimensions.

Material of manufactureStainless steel sealing machines are recommended for humid environments or sectors such as the food industry, where high hygiene is required.