Are you about to automate your production line? Here's what you need to know before choosing packaging machinery

In a market where efficiency makes all the difference, choosing the right packaging machinery can transform your company's productivity. Whether you're looking to renew old equipment or respond to your production growth, this guide will help you make the right choice. Discover the key aspects to evaluate - from product type to available space - and how the right choice can help you reduce costs, gain agility and successfully scale your industrial business.

Choose the suitable packaging machinery is a strategic decision for any company seeking to automate your end-of-lineto gain efficiency and reduce operating costs. Whether to renew obsolete equipment or to accompany production growth, making the right choice among the many options on the market can make the difference in productivity, quality and profitability.

In this guide we explain step by step what to take into account when it comes to choosing packaging machinery The ideal solution, with a practical approach and adapted to both medium-sized companies in expansion as well as large industrial companies. In addition, we discuss when to opt for a standard solution and when to invest in tailor-made machinery.

1. Assess your real need for automation

Before talking about brands or technologies, analyze your current process:

- How many units do you pack per hour/day?

- What repetitive or manual tasks could be automated?

- Are there bottlenecks at the end of the line?

- What impact would automation have on overall efficiency?

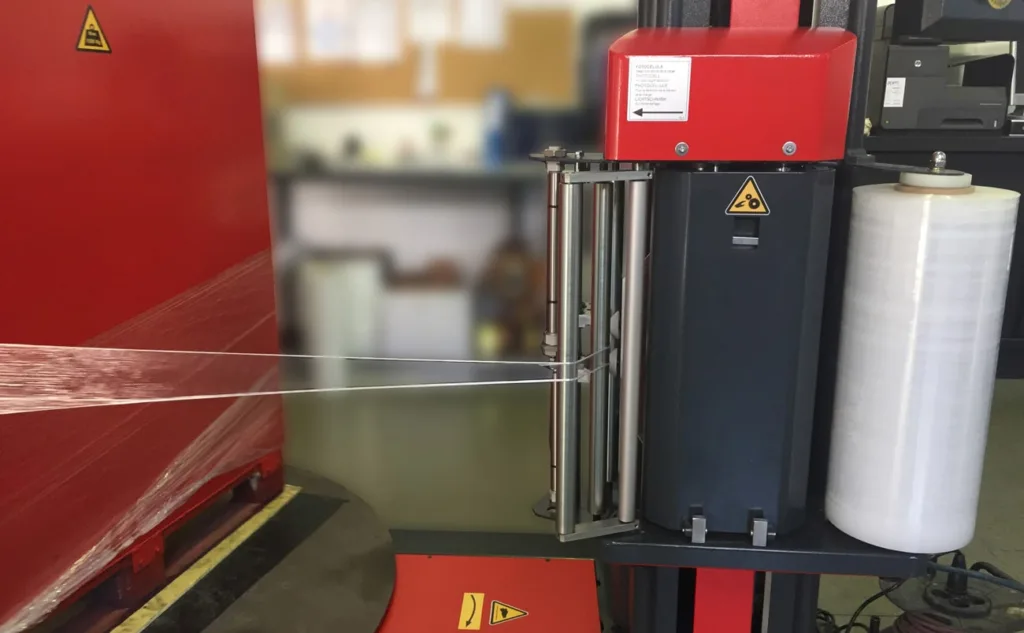

This initial diagnosis will help you define the type of machinery requiredCase erectors, case sealers, wrappers, case packers, palletizers, palletizers, among others..

2. Define the characteristics of the product and packaging

Each packaging line must be adapted to the product and the type of packaging used. Some key points to consider:

- Product dimensions and weight

- Variety of references and format changes

- Type of packaging material (film, cardboard, trays, etc.)

- Sector-specific requirements (food, pharmaceutical, logistics, etc.)

These variables determine whether a standard machinery is sufficient or if you need a customized solution that precisely fits your requirements.

3. Consider the space available in your plant

Machinery must integrate seamlessly into your plant. Evaluate:

- Space available in the end-of-line area

- Possible interference with other machines or logistic flows

- Access requirements for maintenance and cleaning

- Electrical and safety requirements

In cases where space is limited or the layout is complex, opt for tailor-made packaging machinery may be the most efficient option.

4. Betting on scalable and connected equipment

If you're investing in automation, do it with foresight. Modern machinery makes it possible:

- Scalability to increase production capacity

- Industrial connectivity (Industry 4.0) for data analysis and predictive maintenance

- Integration with ERP or logistics systems for full traceability

These elements are especially relevant in companies with intensive production and multiple shifts.

5. Compare total costs, not just the initial price.

Investing in packaging machinery is about much more than comparing quotes. Consider:

- Installation and start-up costs

- Energy consumption and maintenance

- Spare parts availability and technical support

- Estimated useful life and depreciation

Often, the packaging systems can represent a savings in the medium and long term, by eliminating inefficiencies or reducing downtime.

6. Consultation with a specialized supplier

It is not necessary to make this decision alone. An expert manufacturer such as Ihress Premium Packaging Machinery can help you:

- Evaluate your needs with technical criteria

- Design a customized and viable solution

- Ensure regulatory compliance and certifications

- Offer local and international after-sales support

Choosing a supplier with experience in multiple industry sectors is key to obtaining a reliable and tailored solution.

Choosing the right packaging machinery The right decision involves a combination of internal analysis, strategic vision and technical advice. Whether you are looking to improve your efficiency, automate repetitive processes or scale your production, the right decision can translate into a clear competitive advantage.

At Ihress Premium Packaging MachineryWe design solutions adapted to each company, combining technological innovation with industrial experience. We specialize in tailor-made machinery that integrates seamlessly into your production line and meets your business objectives.

Do you want a personalized technical study?

Contact with us and we will help you identify the ideal packaging solution for your company. Our team accompanies you from initial diagnosis to start-up, with premium machinery built to last.