Strapping Machines

Strapping machines premium for industry

Strapping machine for battery

Our battery-powered strapping system, specially designed for easy and comfortable use by the operator, is a leader in the strapping industry.

With a wide range of extensions and applications, we can provide a PP or PET strapping solution with our iMSM300 machine.

Strapping machines Semiautomatic

The semi-automatic strapping machines are perfect for securing packages or boxes by strapping, usually plastic. It is a practical and efficient solution in low to medium volume environments. They are packing machines which require the intervention of the operator, who must place the strap around the product and activate the strapping cycle.

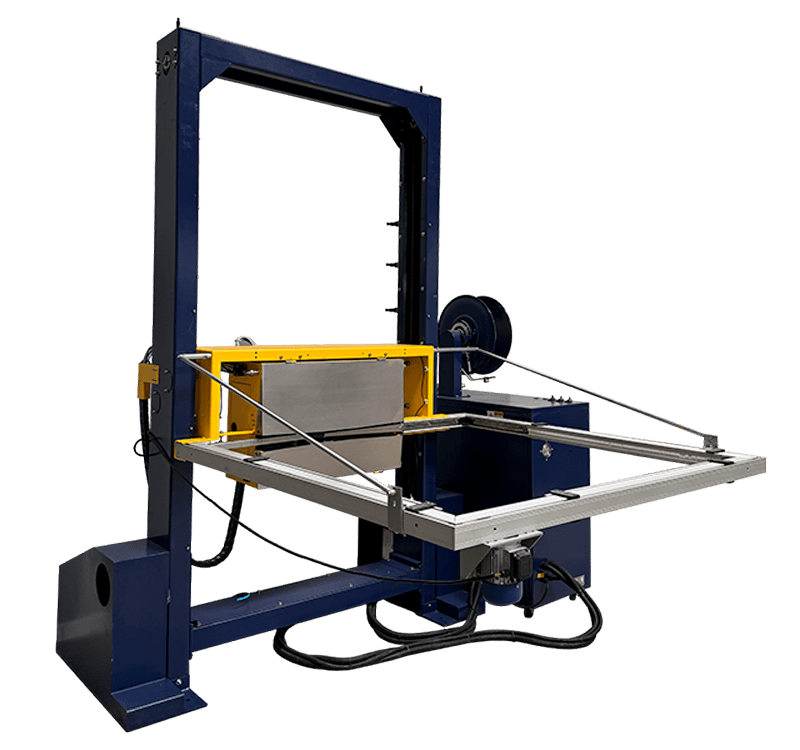

Strapping machines Automatic

The automatic strapping machines are strapping systems specifically designed to secure palletized loads quickly and efficiently. Equipped with a robust structure and an arch surrounding the load, these machines allow the pallet to be positioned in the center of the system for precise strapping. They use PET or PP strapping, ensuring a firm and secure hold that improves stability during transport or storage. They are ideal for industrial environments where high performance and automation in the packaging process are required.

Automatic strapping machines

Vertical and horizontal iFPV-150 / iFPH-150 models

Strapping systems especially suitable for palletized loads. Robust and with an arch around the load, they allow the pallet to be placed in the middle of the system and strapped with PET or PP strapping.

WIDE RANGE OF SOLUTIONS

Get to know our complete catalog of customized solutions for any packaging need your company or business may have.

Frequently Asked Questions about strapping machines

What are the advantages of semi-automatic strapping machines?

Semi-automatic strapping machines are an efficient solution to speed up the strapping process without compromising safety and quality:

Fast and efficient processThey significantly reduce strapping time, improving overall productivity.

Fewer errorsAutomated design minimizes human error, ensuring accurate and safe strapping.

Cost savingsLess strap waste and reduced operating time.

Automatic feedingThe operator only changes the coil when it runs out, allowing a continuous workflow.

Friction sealingGuarantees maximum strapping efficiency without the need for staples or other elements.

What are the features of IHRESS automatic strapping machines?

The automatic strapping machines are designed to be integrated in industrial lines with high volume of work:

Compatibility with multiple palletsThey work with Europallet, half pallet and UK Pallet.

Robust and durable structureDesigned for intensive use and easy maintenance.

Upper head + telescopic lanceThey ensure precision and efficiency in strapping on pallets.

Automatic pallet height detectionAutomatic adjustment of the operation for loads of different sizes.

Strap accumulatorImproves workflow by efficiently retrieving the strap.

Adjustable tension with compensated clampEnsures a firm, constant and safe strapping.

Strap end sensorWarns the operator before the material runs out.

What level of safety do automatic strapping machines offer?

IHRESS automatic strapping machines are designed to offer a high standard of safety:

Load presence sensorAvoids collisions between the telescopic drawbar and the merchandise.

Adjustable strapping forceUp to 90 kg, to adapt to different types of load.

Friction sealingRobust and safe, without the need for additional components.